posted on June 15, 2023 10:30

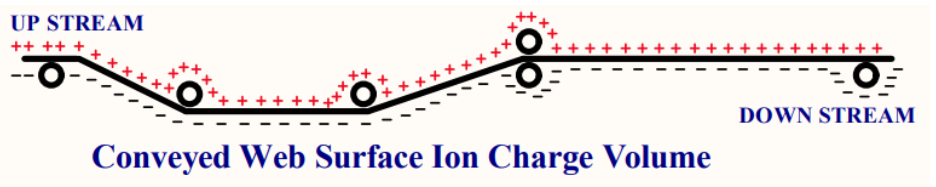

Across a wide array of industries static electricity is the principal obstacle to achieving higher processing speeds and the main cause of quality problems. Significant surface charge levels build up as a by-product of the material being conveyed, Fig 1a.

Fig 1a, Cumulative charges on web material being conveyed.

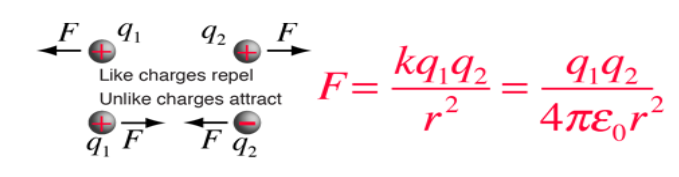

Fundamentally, charges exist as two polarities (+) Positive and (-) Negative ions. The attraction and repulsion force between the two charges is defined by Coulomb’s Law, Fig 1b, which states opposite charges will attract and similar charges will repel each other. The processed conveyed material is in motion, and typically stretched put under surface tension as it wraps along several types of circular rollers made up of chemically dissimilar, insulative or conductive, materials than that is being processed.

Fig 1b, Coulombs Law, electrostatic forces between two similar, and opposite charges.

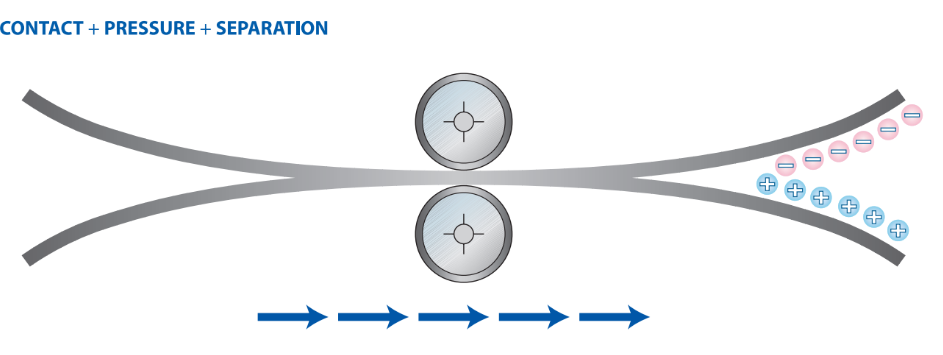

Insulators have their electrons strongly bounded to each atom, this prohibits the movement of charge freely so charge concentrations can be localized and have a natural tendency to spread to the surface because of repulsive forces. Conductors have their electrons loosely bound to each atom so they can move about allowing conductive charge flow within the conductor. These dissimilar insulative or conductive surfaces meet, come in contact with each other, and separate along the circular, curved, tangential contour of the roller, Fig 1c.

Fig 1c, Static Electricity is a function of Friction, Pressure and Contact Separation.

This results in triboelectric charge distribution governed by Gauss’s Law which relates the distribution of electric field and electric flux across an enclosed surface as a function of the electric charge, surface area, and the normal angle that forms between the electric field lines and the web surface. At the contact interface of both, insulative and conductive, surfaces an electron migration exchange takes place such that when the dissimilar surfaces separate the surface material which has giving up electrons becomes (+) Positively charged and the surface that has gained electrons becomes (-) Negatively charged. The charge polarity of each surface is governed by the triboelectric series, which is an organized enumerated list of insulative and conductive materials that can acquire a Positive, Neutral, or Negative charge based on charge strength. These electrostatic charges, now in motion accumulate to high levels, leading to the formation of elevated voltages and currents spread along the conveyed web materials surface and are related to the moving web parameters involved: Web Width [cm], Web Speed [FPM], Material Surface Charge Density [nC/cm2], and roller Velocity [cm/s]. Other charge level dependencies include ambient temperature [oC] and air humidity[g*m3].

Process conveyed web materials have been well known to accumulate high charge concentration levels ranging from 1KV to 100KV. At these charged levels, ambient dust, and fiber particulates cause contamination, manufacturing non-uniformities, material damage, spontaneous arc flash discharge, damage to sensitive programmable logic controllers (PLC) electronics, and becomes a shock hazard to operators putting their safety and of others around them at risk.

As a result of these operational consequences the selection of electrostatic eliminator technology, Passive, or Active: AC, Pulsed DC, or Intelligent Systems, needs to be understood and correctly implemented in the manufacturing process to reduce charge levels to a manageable degree where material damage is reduced, quality yield is improved and operator safety is paramount, with minimal operational down time for maintenance.

ABOUT THE AUTHOR:

Manuel C. Blanco is a Senior Electrical Design Engineer at Simco-ION, an ITW company, He has a B.S in Applied Physics & Physics from Seton Hall University, and both a B.S. and M.S. in Electrical Engineering from the New Jersey Institute of Technology. He is an active member of the Electrostatics Society of America (ESA), IEEE Power Electronics Society (PELS), IEEE Industrial Electronics Society (IES), and is a Senior member of the IEEE.