How Is Static Generated?

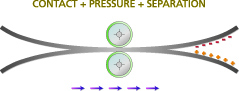

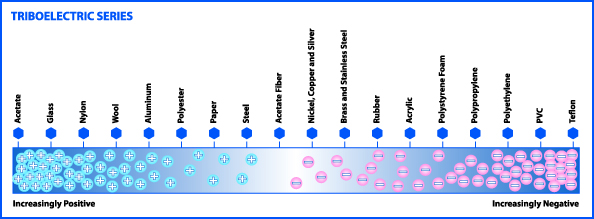

Static electricity is a surface phenomenon and results when two or more surfaces are in intimate contact with each other and then are separated. During contact, surface electrons, which are negative, migrate from one surface to the adjacent surface. When the surfaces separate, the surface that gains the electrons becomes negatively charged, the surface giving them up becomes positively charged.

Many industrial materials are insulators, such as rubber, glass and plastics. Their desirable qualities make them essential to use; however, they are likely to become electrostatically charged during processing.

Why Is Static Control Important?

Managing static electricity is important for several reasons, the most notable being contamination control, operator safety, and minimizing process equipment issues that can occur due to high static charges. Many industrial materials are insulators, such as rubber, glass and plastics. Their desirable qualities make them essential to use, however, they are likely to become electrostatically charged during processing. These processes include:

- Peeling laminate

- Unwinding a roll

- Separating surfaces

- Wind-up operations

- Collecting products in bins

Production jams, quality problems, dirt attraction and rejects are all consequences of uncontrolled static. The biggest issue for most manufacturers is that all of these problems resulting from static electricity impact their bottom-line.

For more information about our products and services please fill out the form below and one of our representatives will contact you shortly.